Introduction

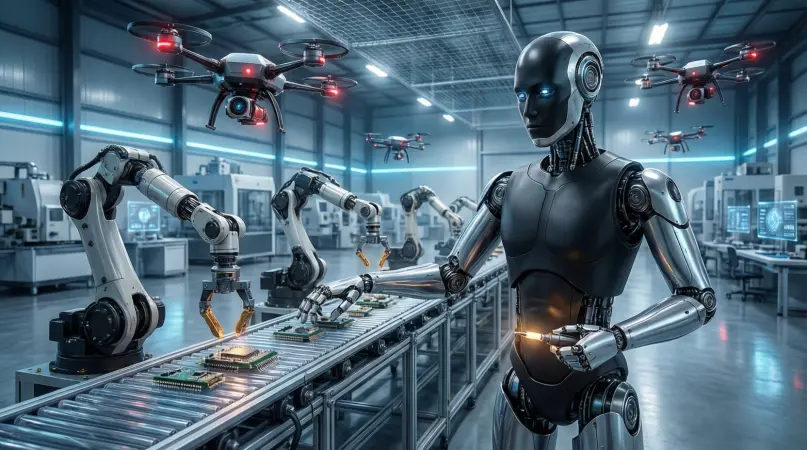

Robotics and automation are no longer concepts of the distant future. They are transforming the way we live, work, and interact with technology today. From smart factories to self-driving cars, robotics and automation are becoming central to industries worldwide. They allow machines to perform tasks that once required human intelligence and effort, making processes faster, safer, and more efficient.

For beginners and intermediate learners, understanding robotics and automation is essential. Not only is it shaping career opportunities, but it also influences everyday life. Imagine factories where machines assemble products without human intervention, or hospitals where robotic systems assist surgeons in performing precise operations. These technologies are not limited to large organizations; small businesses, startups, and even homes are starting to benefit from automated systems.

What is Robotics & Automation?

Robotics refers to the design, construction, operation, and use of robots—machines that can carry out tasks automatically or with minimal human input. Automation, on the other hand, is the use of technology to perform tasks without constant human intervention. When combined, robotics and automation create systems that can operate independently or alongside humans to increase efficiency.

Key points to understand:

- Robots are programmable machines that can perform repetitive or complex tasks.

- Automation is the broader concept that applies to processes, machinery, and even software systems to reduce human labor.

- Integration of robotics and automation allows industries to achieve higher productivity, lower errors, and improved safety.

Examples of robotics and automation include:

- Automated assembly lines in manufacturing

- Robotic vacuum cleaners for homes

- Autonomous drones for delivery

- AI-powered chatbots in customer service

By understanding the basics, you can see how robotics and automation are not just limited to industrial applications—they are becoming a part of everyday life.

Why is Robotics & Automation Important?

The importance of robotics and automation cannot be overstated. It affects businesses, society, and personal life in numerous ways:

- Increased Efficiency: Machines work faster and more accurately than humans in repetitive tasks.

- Cost Reduction: Automation reduces labor costs and minimizes errors, saving money in the long run.

- Improved Safety: Robots can perform dangerous tasks that could harm humans, such as handling chemicals or heavy machinery.

- Consistency: Automated systems maintain quality standards consistently, which is crucial in manufacturing and healthcare.

- Innovation Opportunities: Automation opens doors to new business models, like smart logistics and AI-driven services.

For industries like manufacturing, healthcare, logistics, and agriculture, robotics and automation are not optional—they are essential to remain competitive. For individuals, understanding these technologies can lead to better career opportunities and informed decisions about technology adoption.

Detailed Step-by-Step Guide to Robotics & Automation

Step 1: Understanding the Basics

Before diving into practical applications, start with the fundamentals:

- Learn the difference between robotics and automation.

- Familiarize yourself with types of robots, such as industrial robots, service robots, and collaborative robots (cobots).

- Study basic automation processes, including mechanical, electronic, and software-based automation.

Step 2: Identify Your Goals

Ask yourself:

- Are you implementing robotics for business efficiency?

- Do you want to build robots as a hobby?

- Are you seeking to enhance your career in automation technologies?

Your goal will determine the tools, software, and level of investment required.

Step 3: Choose the Right Tools

Depending on your objectives:

- Industrial Automation: PLCs (Programmable Logic Controllers), SCADA systems, robotic arms.

- Home/Small Business Automation: Smart devices, IoT systems, automated workflow software.

- Learning & Prototyping: Arduino, Raspberry Pi, and simple robotic kits.

Step 4: Design & Programming

- Robotics design involves mechanical, electrical, and software components.

- Programming can range from simple coding (Python, C++) to advanced AI algorithms for autonomous robots.

- Simulation software allows testing before real-world implementation, reducing errors.

Step 5: Integration

Integrating robots and automation into your environment requires:

- Ensuring compatibility with existing systems

- Planning workflows to maximize efficiency

- Training humans to work alongside machines safely

Step 6: Testing & Monitoring

- Run trial processes to identify issues

- Monitor robot performance and gather data

- Optimize the system for better results

Step 7: Maintenance & Updates

- Regular maintenance ensures longevity and reliability

- Software updates keep robots aligned with current standards

- Continuous improvement leads to higher efficiency

Benefits of Robotics & Automation

Implementing robotics and automation brings multiple advantages:

- Higher Productivity: Machines work 24/7 without fatigue.

- Accuracy & Precision: Reduces human error, especially in manufacturing and surgery.

- Cost Savings: Long-term reduction in labor and error-related costs.

- Safer Work Environment: Robots handle hazardous tasks.

- Consistency: Ensures uniform quality and performance.

- Flexibility: Modern robots can adapt to new tasks with minimal reprogramming.

- Innovation Boost: Automation frees humans to focus on creativity and problem-solving.

Example: Automotive factories use robotic arms to assemble cars efficiently, reducing production time while maintaining consistent quality.

Disadvantages / Risks

Despite its benefits, robotics and automation come with challenges:

- High Initial Costs: Setting up automated systems can be expensive.

- Job Displacement: Some manual jobs may become obsolete.

- Complexity: Advanced robots require skilled operators and maintenance.

- Technical Failures: Malfunctions can halt production or cause accidents.

- Cybersecurity Risks: Connected automated systems may be vulnerable to hacking.

- Limited Adaptability: Some tasks still require human judgment and creativity.

It’s important to weigh these risks when planning to implement robotics and automation in any setting.

Common Mistakes to Avoid

- Skipping Planning: Implementing automation without a clear strategy leads to wasted resources.

- Ignoring Human Training: Employees need to adapt to new systems; neglecting this causes inefficiency.

- Over-Reliance on Automation: Not every task should be automated; humans are still essential for critical decisions.

- Neglecting Maintenance: Poor maintenance reduces reliability and increases downtime.

- Underestimating Costs: Initial setup and training expenses are often overlooked.

- Neglecting Data Security: Automated systems require robust cybersecurity measures.

Avoiding these mistakes ensures a smooth and successful robotics and automation experience.

FAQs

1. What is the difference between robotics and automation?

Robotics is about building and programming machines to perform tasks, while automation refers to using technology to execute processes with minimal human input. Robotics is a subset of automation.

2. Can robotics replace human workers entirely?

Not entirely. While robots excel in repetitive or dangerous tasks, humans are still needed for creativity, problem-solving, and complex decision-making.

3. How can beginners start learning robotics?

Start with small projects using Arduino or Raspberry Pi kits. Online tutorials and robotics courses can help you understand programming, sensors, and mechanical design.

4. Are robotics and automation expensive?

The initial investment can be high, especially for industrial applications. However, long-term benefits like increased efficiency and reduced labor costs often outweigh the initial expense.

5. What industries benefit the most from automation?

Manufacturing, healthcare, logistics, agriculture, and customer service are key sectors that benefit from robotics and automation.

6. How safe is working with robots?

Modern robots are designed with safety features like sensors and emergency stop functions. However, proper training and maintenance are essential to prevent accidents.

7. What skills are needed for a career in robotics?

Important skills include programming (Python, C++), mechanical design, electrical engineering, problem-solving, and familiarity with AI and machine learning.

8. Can small businesses use robotics and automation?

Yes. Small businesses can implement automation through software, smart devices, or low-cost robotic kits to improve efficiency and reduce repetitive tasks.

Expert Tips & Bonus Points

- Start Small: Begin with simple automation projects to understand workflows.

- Continuous Learning: Robotics is constantly evolving; stay updated with the latest technologies.

- Prioritize Safety: Always follow safety protocols, especially in industrial environments.

- Invest in Training: Skilled employees maximize the potential of automation.

- Integrate Data Analytics: Automated systems generate valuable data; use it to improve performance.

- Think Long-Term: Focus on scalability and adaptability when implementing robotics.

- Collaborate with Experts: If possible, work with professionals for complex robotic systems.

Bonus Tip: Combine robotics with AI to achieve autonomous decision-making, predictive maintenance, and smarter processes that adapt to changing needs.

Conclusion

Robotics and automation are revolutionizing industries and shaping the future of work. They increase productivity, reduce costs, and improve safety, making them indispensable in modern society. From manufacturing floors to everyday homes, these technologies are enhancing efficiency and opening doors to innovation.

However, they also come with challenges, such as high initial costs, job displacement, and technical complexities. By understanding these factors, avoiding common mistakes, and following expert tips, individuals and businesses can leverage robotics and automation effectively.